BOISE, Idaho (Washington Insider Magazine) – Idaho National Laboratory scientists have finished a rare overhaul of one of the world’s most efficient nuclear test reactors, and standard operations are likely to commence later this spring, according to authorities.

The Advanced Test Reactor, or ATR, in eastern Idaho, was closed down for 11 months to allow for a core refurbishment, which is conducted every Ten years on average. It was the reactor’s 6th changeout since it began operations in 1967, and the first one in 17 years.

The coronavirus outbreak and supply chain complications, according to Sean O’Kelly, associate lab director at the Idaho National Laboratory’s Advanced Test Reactor Complex, prompted some setbacks further than the best scenario of concluding the job in 9 months.

Research at the reactor includes helping the US Navy’s nuclear-powered battle fleet remain at sea longer, NASA’s space travel, and life-saving medical procedures. The reactor is also important in the endeavor to keep commercial nuclear energy plants operational for longer periods of time while also developing new, safer reactors to minimize greenhouse emissions.

Last month, the reactor’s most recent maintenance was finished, and it is now undergoing low-power system inspections, readiness inspections, and instrument calibrations. These evaluations should be completed in May or June.

The reactor is set up to execute many experiments at the same time. According to ABC NEWS, some of the greatest testing slots have a ten-year wait for room to conduct experiments, while others are reserved years ahead of time.

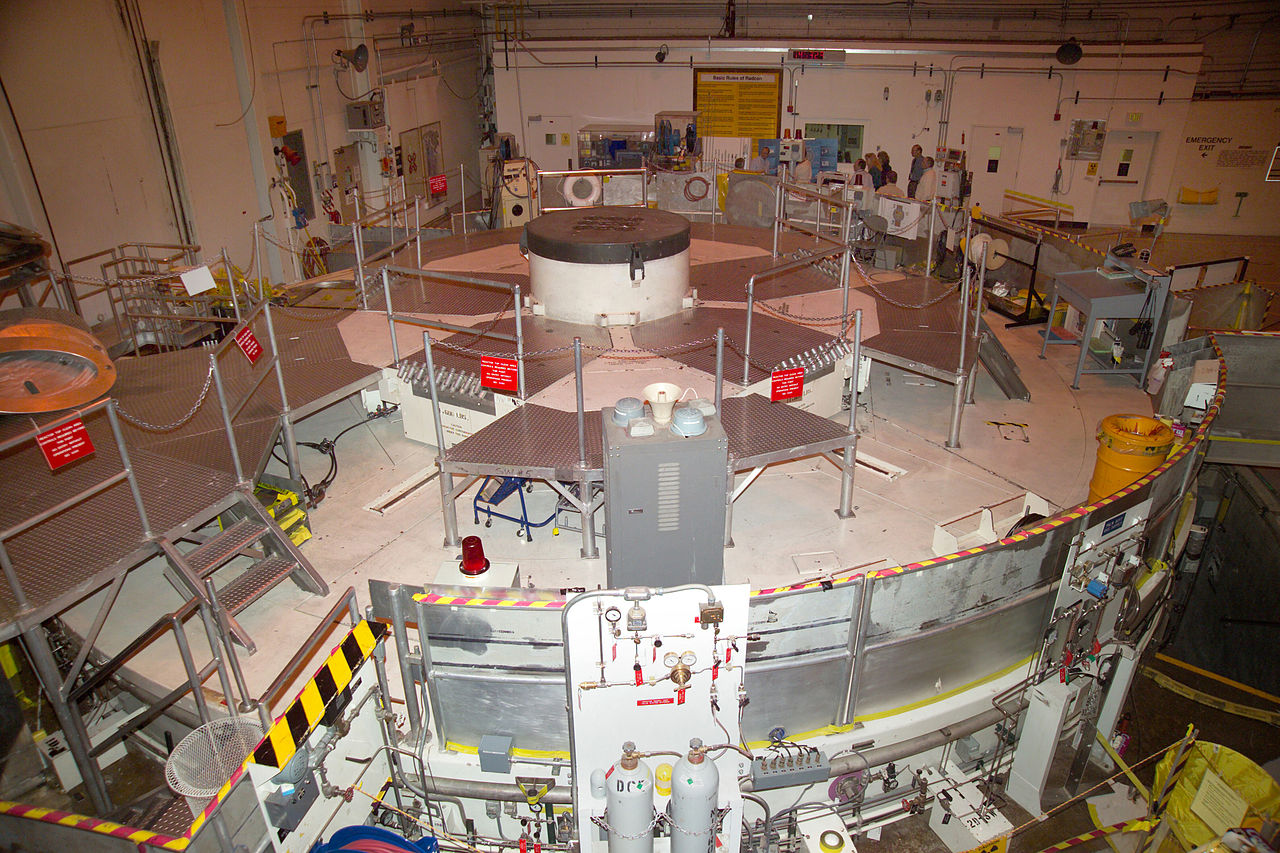

The ATR is unusual in that, unlike conventional nuclear reactors, which create heat that is converted into electricity, the ATR produces neutrons, which may be used to test new materials and fuels in high-radiation conditions. The cloverleaf design of the test reactor has a core ringed by beryllium metal to reflect neutrons.

However, all of those neutrons wear down the test reactor’s interior components, causing it to lose its capacity to conduct tests if it is not reconditioned.

The reactor’s engineers anticipated this issue and designed a reactor with internal parts that can be updated on a regular basis.